GCI Oil & Gas is a 100% Mexican company that operates throughout the country. Our portfolio includes specialized services in the structuring, management, and execution of projects in the gas and hydrocarbon exploration and production, petrochemical, and energy sectors.

¿Quiénes somos?

“OUR SERVICE EXCELLENCE IS NOT AN ACHIEVEMENT, IT IS OUR SPIRIT, IT IS OUR PASSION.”

Quality Objectives

- Promote the professional development of our employees, strengthening their skills and competencies.

- Build trust with customers and stakeholders by meeting quality standards in our products and services.

- Manage available resources efficiently to ensure effective project development.

- Promote continuous improvement by applying best practices aligned with the Quality Management System.

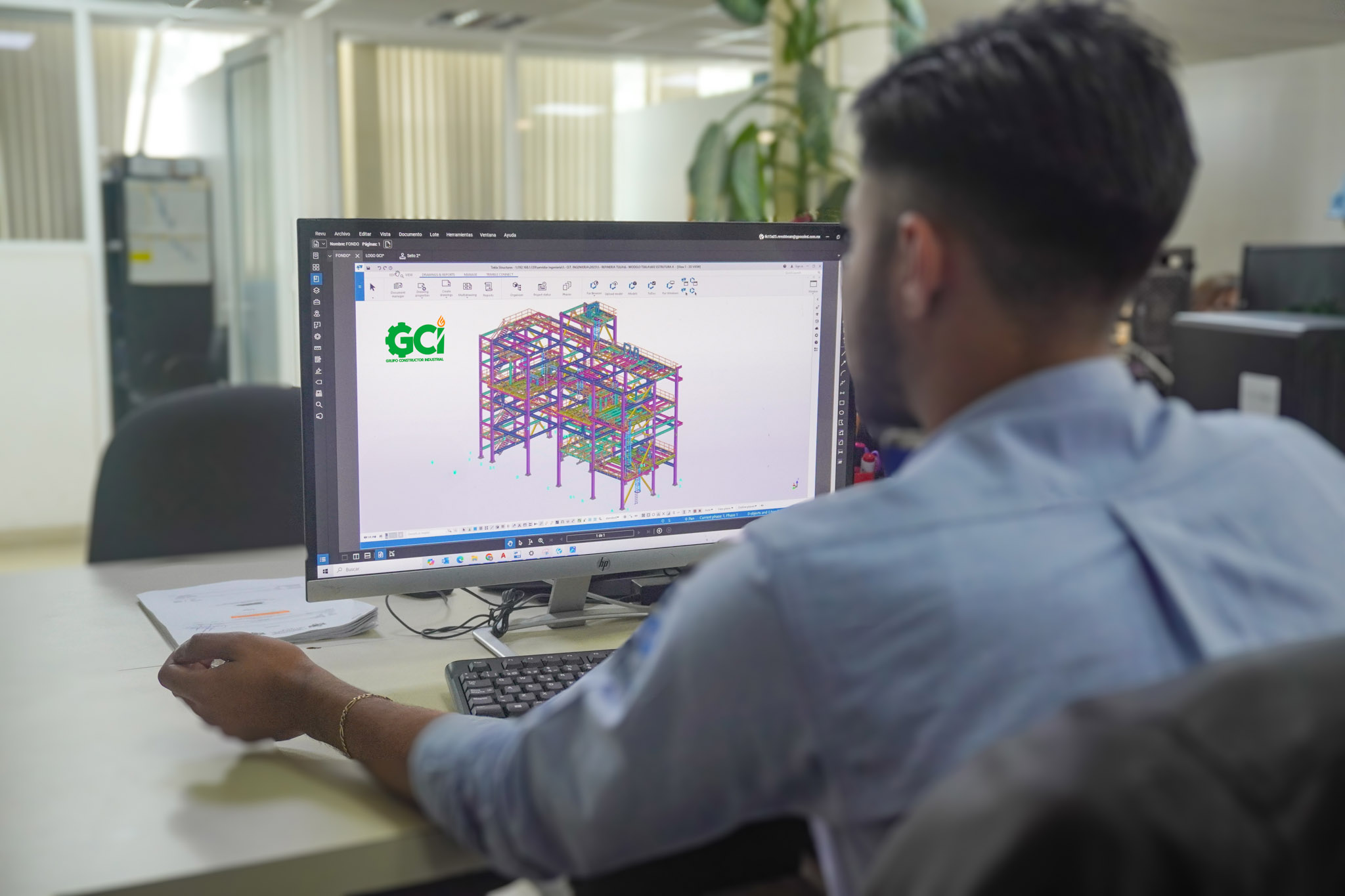

Engineering

The engineering development process at the Grupo Constructor Industrial S.A. De C.V. workshop is at the forefront of the industry, supported by specialized software for steel structures. tekla structures is our primary design tool, enabling us to execute projects of any scale within relatively short timeframes, it also provides essential support tools for the manufacturing and assembly of steel structures.

currently, Grupo Constructor Industrial s.a. de c.v. has the capacity to develop over 32,000 tons of semi-heavy steel structures annually. our multidisciplinary team brings extensive experience that allows us to deliver high-level engineering, ensuring the success of every project we undertake. the expertise within our team also enables us to carry out rigorous analysis following current standards and regulations, facilitating agile and effective decision-making to meet the specific needs of each project.

Quality

We are a company committed to delivering specialized, high-excellence services in the structuring, management, and execution of projects focused on the exploration and production of gas and hydrocarbons, as well as the petrochemical and energy sectors. We ensure the successful completion of each project under strict quality standards, contributing to sustainable development and achieving total customer satisfaction.

Our processes are not only aligned with contractual requirements but are also supported by both national and international standards, ensuring consistency, compliance, and continual improvement.

- CWI Welding Inspector

- CAWI Welding Inspector

- Certified Liquid Penetrant Inspectors

- Tightness inspection by ASNT (Certified Level II).

- Hydrostatic test

- Pneumatic test

- FAT tests.

Maquinaria y Equipos

PEDDINGHAUS PCD 1100

This equipment has a cutting saw and drills on the Y, X and Z axes which make holes in beams (H), angles, channels and plates using CNC programs

PEDDINGHAUS PCD 1100 Model PCD 100/3B

This equipment has drills on the Y, X and Z axes which make holes in profiles such as beams, angles, channels and plates using CNC programs.

PROFILE CUTTING SAW 1020 C

Semi-automatic equipment for cutting profiles, using the band saw as the cutting medium.

DURMAN 1100 SIERRA

This semi-automatic equipment is designed for enabling profiles, it has a control panel for cutting speed.

SIERRA DURMAN 560

This semi-automatic equipment is designed for enabling profiles, it has a control panel for cutting speed.

LINEA DE PERFILES M&G.

This equipment has a band saw for cutting profiles and drills on the Y, X and Z axes which make holes, oblongs and machining.

PLASMA HPR 400 HYPERTHERM

3-axis Hypertherm plasma, with smoke mitigation using a water bed, using oxygen, nitrogen and air.

PLASMA HPR 400 HYPERTHERM

3-axis Hypertherm plasma, with smoke mitigation using a water bed, using oxygen, nitrogen and air.

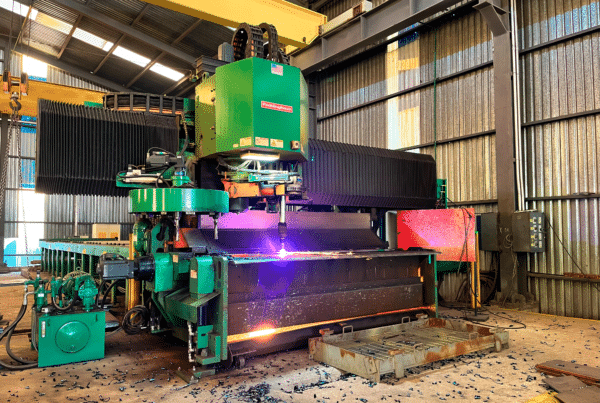

PLASMA Y BARRENADORA DE PLACA PEDDINGAHUS HSFDB 2500 C

A drilling, milling, countersinking, oxyfuel, plasma, marking and stamping machine and a 12-station tool changer. Constant material output. Uses air, oxygen and nitrogen.

PLASMA HPR 400 SPIRIT II LINCOLN

Manual plasma cutting system with high definition fineline technology with a 100% duty cycle controlled by a 400 amp microprocessor.

GEKA 80-110 SD PUNZONADORA Y CIZALLA

It has a punching station, three bar and angle cutting stations. Its punching power is 110 tons and two independent work stations, which allows two tasks to be carried out simultaneously.

LASSER CUTTING MACHINE FOR PIPES

It has a punching station, three bar and angle cutting stations. Its punching power is 110 tons and two independent work stations, which allows two tasks to be carried out simultaneously.

TORNO CNC

It has a punching station, three bar and angle cutting stations. Its punching power is 110 tons and two independent work stations, which allows two tasks to be carried out simultaneously.

SHOTBLASTING MACHINE

It has a punching station, three bar and angle cutting stations. Its punching power is 110 tons and two independent work stations, which allows two tasks to be carried out simultaneously.